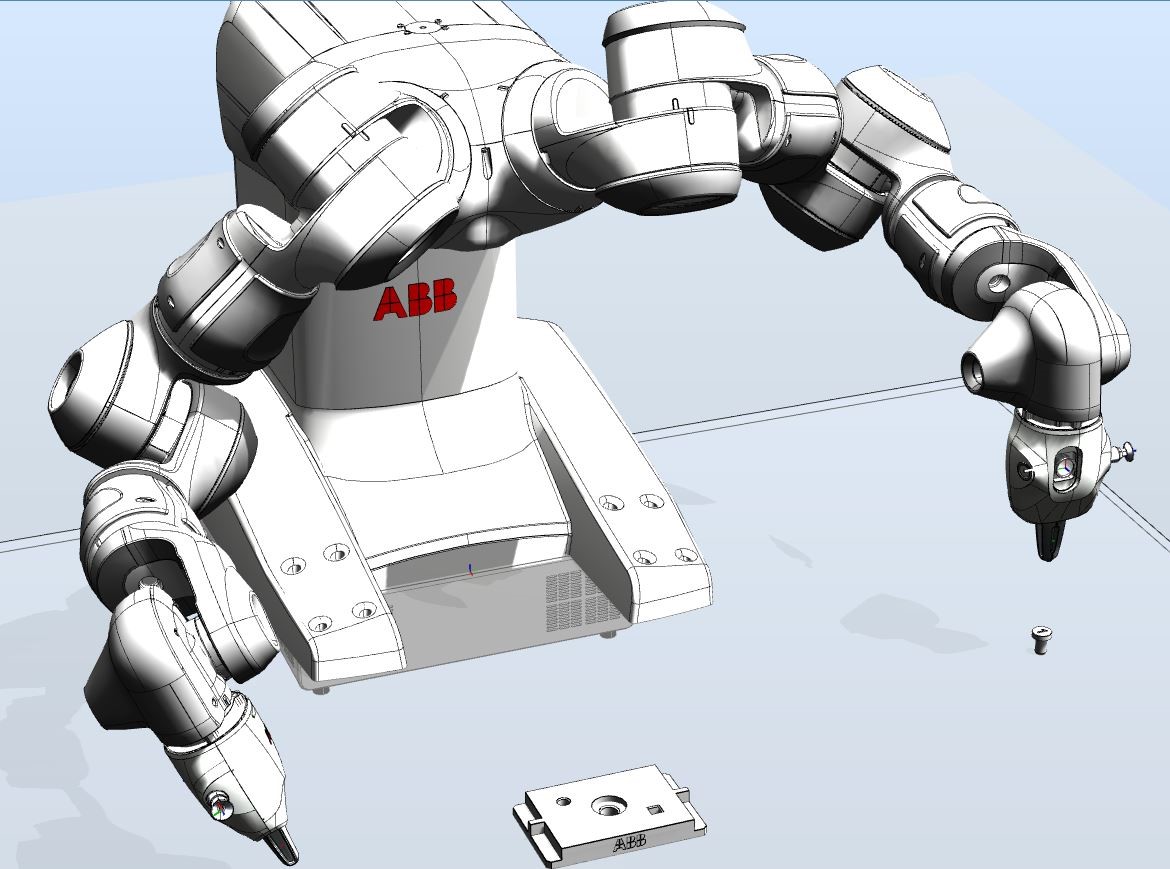

The search for optimal parameters – ABB Robots learn in simulation

Industrial robots are designed and programmed to do desired tasks proficiently, efficiently, robust, and reliably. Productive4.0 partner ABB, in terms of turnover the second largest robot provider worldwide, sees significantly increasing requirements on the skills of the robot systems due to the rising demand on the flexibility of production and the ease of using them.

To support achieving this goal, our Swiss project partner developed machine learning based methods and proof of concept demonstration in its use case in work package 8. The preliminary results were presented during the consortium meeting in March 2019.

In the context of Automation and Digitalisation, ABB is enabling manufacturing sites to become increasingly adaptable and scalable to new production needs. Industrial robots now provide intelligent task-level functions, which can adapt to different situations and variations in the real world – you could call these “robot skills”. “Consequently, when there are deviations in the robot station, the robot can be empowered to not halt operation but to rather search for an alternate solution,”ABB says.

Tackling such industrial problems in simulation is particularly advantageous as explorative learning with real robots can be dangerous, costly or not feasible. ABB RobotStudio and virtual controllers provide an appropriate environment to model and accurately simulate robot stations including robot programme execution. A sophisticated learning infrastructure leverages running of simulations in parallel and thus, offers scalability.