Bag-Era is a young start-up from CEA-Leti. It proposes software solution to coordinate heterogeneous

systems composed of software and hardware components. This software layer provides high level

mechanisms and properties in order to decrease the amount of work required to build application. For

instance, it ensures consistency of the system even in case of failures (network, communication link,

hardware and software components.

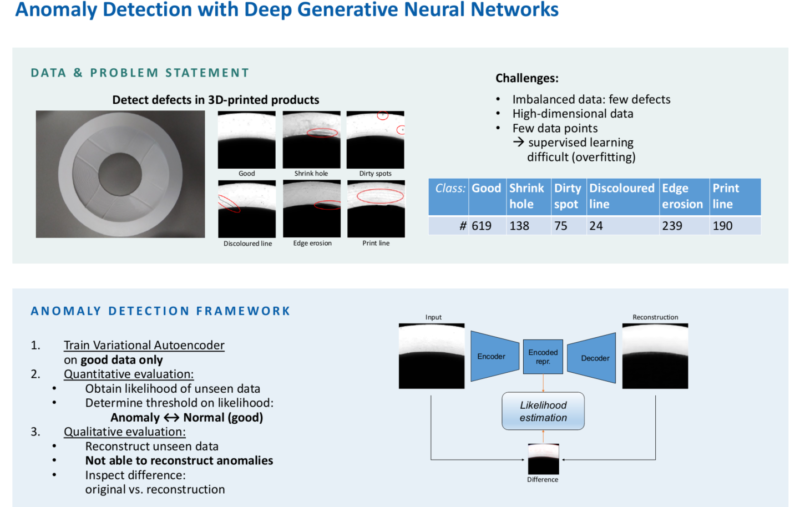

- Task 8.3.5 Factory Supervision for variability reduction (ST Crolles, CEA-Leti, Bag-Era) ST CROLLES, together with CEA and Bag-era will develop a proof-of-concept for a smart diagnostic system, starting from the monitoring of KPIs and allowing the identification / allocation of root causes to operators.

- CEA Logo du CEA

- STMicroelectronics Crolles 2 SAS