The French Alternative Energies and Atomic Energy Commission (CEA) is a key player in research, development and innovation in four main areas: defence and security, nuclear and renewable energies, technological research for industry, fundamental research in the physical sciences and life sciences.

Since it was first set up, the CEA has been involved in transferring scientific knowledge and innovation “from research to industry”.

- technical contribution (WP1, WP5 and WP8) and dissemination activities (WP10)

- WP8: CEA will bring its expertise in coordination middleware (LINC). It will be used to allow hot smart reconfiguration (both negotiated and transactional) of the whole system, combining information coming from raw information/alerts or combined alerts/conditions, taking into account context and dynamic aspects of the fab and ensuring functional consistency at global system level. In collaboration with ST CROLLES and BAG-ERA, CEA will demonstrate the supervision/coordination of a global system by providing a functional prototype and its GUI

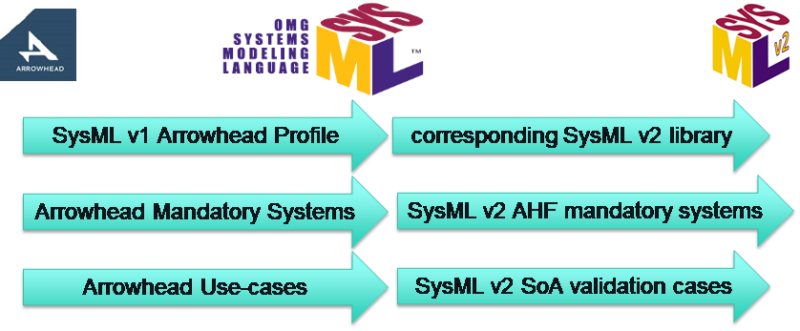

- WP1: safety and security properties within the Arrowhead Framework: from design architecture to rapid prototyping of CPS; ensuring coherence between WP1 and WP8 CEA contributions on the ST use case

- WP5: CEA will bring its expertise on dataflow / workflow model of computation combining scheduling approaches and real time constraints to model workflows in the factory and supply chain model, focusing on the semi-conductor industry and equipment providers.

- Agileo Automation

- BAG-ERA

- STMicroelectronics Crolles 2 SAS